MTS PREMIUM STUDIO LIGHTING SUSPENSION

ABOUT MTS CONTROL UNITS

Our motorized studio lighting suspensions are powered by a decentralized control logic, minimizing downtime and ensuring maximum operational readiness. Each suspension device is equipped with an independent motor control unit, which continuously monitors all safety-critical parameters, including:

- Overload protection

- Slack-rope detection

- Cable breakage detection

- Upper and lower working end positions

- Upper and lower emergency stop positions

Our system offers scalable automation levels, ranging from simple up/down controls to standard control panels with group selection (FCP 900) and fully automated studio control units (FCP PRO).

OUR DIFFERENT CONTROL UNITS VErSIONS:

1) FCP PRO – FULLY AUTOMATED RIGGING CONTROL

- big touch LDC display (21,5″) FULL HD

- intuitive GUI with customizable studio layout

- fully automated studio control

- safe- and recall positions

- available in desk- and 19″rack-version

2) FCP 900 – STUDIO CONTROL .

- standard control unit

- controls 1 – 900 devices

- group selection of up to 10 devices

- simple layout

- backlit touch-buttons and display

3) CONTROL FOR INDIVIDUAL DEVICES.

- wireless remote control units or simple wired control-boxes

1) FCP PRO - ADVANCED RIGGING CONTROL

The FCP Pro is one of the most advanced rigging control systems on the market, designed with a strong focus on safety, user-friendliness, and reliability.

It enables seamless control of hoist systems, telescopes, pantographs, and even mixed equipment or third-party products.

Key features include:

- Large color touch display for intuitive operation

- Group & individual control of lifting devices

- Scenario management – Select, Save, Recall

- Joystick control with confirmation button for precise movement

The innovative user interface is clear and self-explanatory, allowing different authorization levels for operators. In supervisor mode, the studio layout can be easily customized and updated by an administrator to accommodate future expansions.

- Modern wide LCD color touch display, 21,5″, FULL HD (1920x1080px)

- ideal to control vertical and horizontal position

- Integrated joystick for movement of selected devices

- USB port for software upload

- Emergency stop switch

- Access protection with passoword and key

- Bi-directional data transfer in real time between panel

- Status feedback of each device (such astop or bottom end position, overload, slack rope)

- Graphical User Interface shows actual studio layout and can be easily edited

- Controls infinite amount of devices

- Wired and Wireless remote control available

- Safe, store and recall groups of devices

- edit the studio layout by adding or deleting devices or repositioning them

- Allows selection of individual or multiple devices

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- TÜV tested system

- Different user profiles

- Standard User

- Supervisor

- Shows actual studio layout

- easily add and delete devices in “Supervisor Mode”

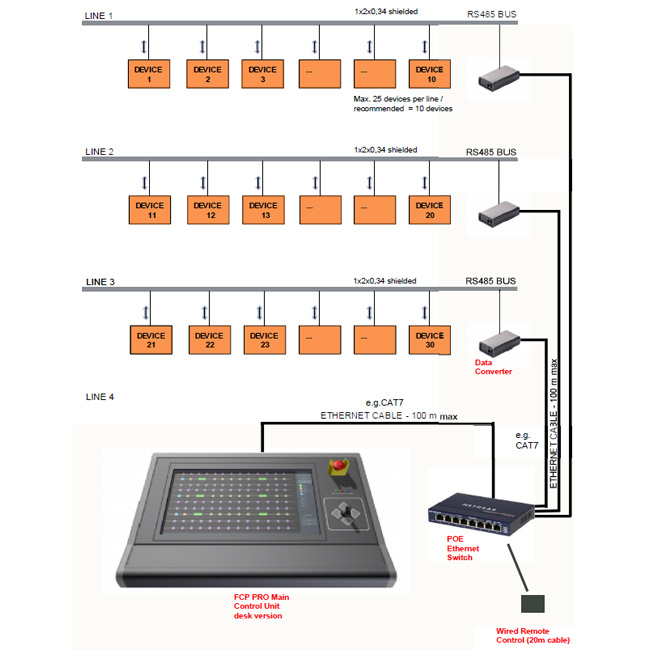

The FCP 900 Pro Studio Control unit consists of several main components:

- FCP Pro – Computer control (A – 19“ Rack version; B – Desk Version)

- POE Switch 1 Gbit/s – Ethernet switch with a speed of 1 Gbit/s

- Ethernet Board (EB01) – Signal converter Eth./RS485

- Device Board (DB01) – terminal board RS485

HOW IT WORKS!

Join Kenneth and Felix as they introduce the FCP Pro, our state-of-the-art fully automated studio rigging control system. In this video, they showcase its advanced features, intuitive operation, and the unmatched flexibility it offers.

Watch now to see how FCP Pro sets new standards in safety, efficiency, and ease of use for modern studio environments.

The FCP 900 Pro Studio Control unit consists of several main components:

- FCP Pro – Computer control (A – 19“ Rack version; B – Desk Version)

- POE Switch 1 Gbit/s – Ethernet switch with a speed of 1 Gbit/s

- Ethernet Board (EB01) – Signal converter Eth./RS485

- Device Board (DB01) – terminal board RS485

The FCP Pro Control System features an intuitive and user-friendly Graphical User Interface (GUI), designed for seamless operation.

After user authentication (password and key-protected), operators can access multiple control options for the suspension devices through a set of clearly structured virtual buttons:

- REMOTE – Wireless control via remote

- MANUAL – Precise control of individual devices

- SCENE – Save and recall preconfigured scenes

- GROUP – Operate multiple devices as a group

- LOGOUT – Securely log out of the current session

- INFORMATION ICONS – Five system and device status indicators

- DATE & TIME – Display of real-time system information

- OPTIONS – View height, distance, or basket lighting values

- ZOOM – Zoom in, zoom out, or display the full studio layout

At any time, the system provides a clear and comprehensive overview of each device’s position (vertical/horizontal), selection status, and operational state.

A built-in logbook records all movements for complete traceability. To initiate device movement, operators must activate the confirmation button on the joystick, ensuring an added layer of safety.

2) FCP 900 - rIGGING cONTROL

The FCP 900 is a compact, user-friendly control panel designed for managing lighting suspension systems in small to mid-sized TV and film studios. Available in both wired and wireless versions, it offers all essential functions for on-site rigging control.

With the ability to operate individual devices or groups of up to 10 units, the FCP 900 provides flexible, intuitive control at your fingertips. The brightly backlit touchscreen and keyboard ensure excellent visibility in low-light environments, while multi-user access is protected by password and key-based security.

When paired with the RFS-TC4 wireless telecommander, users can precisely position individual lifting devices anywhere in the studio or on stage. Fully compliant with all relevant safety standards, the FCP 900 is engineered for efficiency, precision, and safe operation.

- Versions available:

- Wireless

- Wired

- 19″ Rack version

- backlit buttons and display

- controls up to 10 devices at a time

- you can save and recall 8 groups of up to 10 devices

- passwort protected user access

- key protection

- safe data transmission

- built in emergency button (wired version)

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

3) RFS TC4 - WIRELESS REMOTE UNIT

The RFS-TC4 is a portable wireless controller designed for individual control of studio suspension devices. It can operate in standalone mode—communicating directly with suspension units via onboard radio receivers—or work seamlessly as part of a larger rigging control system, such as the FCP 900 or FCP PRO.

Engineered for reliability and ease of use, the RFS-TC4 features a bright backlit display for clear visibility and a durable, ergonomic housing built to withstand daily studio use. User access is protected by password authentication, ensuring secure operation in professional environments.

Whether used on stage or in the studio, the RFS-TC4 offers precise, mobile control exactly where you need it.

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

WHY CHOOSE MTS PRODUCTS?

Whether you need a fully automated system or basic manual control, MTS offers a complete range of control units tailored to your project’s size, complexity, and workflow. From advanced studio operations to simple setups, MTS gives you total control—your way.

Key Benefits:

✔ Tailored Automation – From fully automated rigging control (FCP PRO) to group control (FCP 900) and basic up/down buttons, we offer control solutions for every level of automation.

✔ User-Friendly Interfaces – Intuitive layouts with bright backlit displays and touch keyboards make operation clear and simple, even in dark studio environments.

✔ Secure Access – All control units feature password and key-based protection to ensure only authorized use.

✔ Wireless & Wired Options – Combine fixed control panels with wireless handheld units (RFS-TC4) for precise local control directly on stage or in the studio.

✔ Flexible Group Control – Operate individual devices or groups of up to 10 units simultaneously with real-time feedback.

✔ Compliant & Future-Proof – Fully compliant with EN 17206 and all relevant safety standards, ensuring long-term legal and functional reliability.

MTS Expertise:

✔ 25+ years in studio & stage lifting

✔ Premium components for safety & durability

✔ Manufactured to DGUV 17 & DIN 56950-2 standards

MTS delivers end-to-end solutions – from consultation to installation, ensuring top-tier safety, performance, and reliability.

MTS Control UNits IN REAL-Life PROJECTS:

MTS control systems power leading studios and venues across the globe.

Our control units are installed in some of the most advanced broadcast and event facilities, delivering safe, reliable, and efficient rigging control for lighting suspension systems. From major national broadcasters to cutting-edge cultural venues, MTS is a trusted partner in precision rigging technology.

RTVE, Madrid, Spain

Humboldt Forum, Berlin, Germany

Česká Televize, Czech Republic

Mediacorp Singapore

- Westdeutscher Rundfunk

…and many many more.

We are proud to support many of the world’s top broadcasters and institutions, providing control solutions that meet the highest standards in safety, flexibility, and performance.

Further questions?

contact us

CONTACT MOVIETECH

- Producs of MTS Media Technical System are globally distributed by MovieTech in Munich, Germany.

E-maIL US

- info@movietech.de