MTS PREMIUM STUDIO LIGHTING SUSPENSION

OH NOO…

THIS PAGE IS CURRENTLY UNDER CONSTRUCTION.

IN CASE YOU CANT WAIT, PLEASE CONTACT US AND WE´ll HAPPILY SUPPLY YOU WITH ALL NECCESSARY INFORMATION.

ABOUT MTS TELESCOPES

MTS studio telescopes enable individual control of each luminaire, offering exceptional flexibility for stage and studio lighting. In fully automated studios, they ensure rapid format changes with minimal downtime. Available in manual and motorized versions, they feature a self-locking gearbox for safe and smooth vertical adjustment.

Constructed from high-strength aluminum, our telescopes are designed for stability and precision. Advanced toothed tube guides ensure minimal radial play, enhancing stability.

For seamless operation, power and data supply is managed via custom-developed hybrid spiral cables, preventing wear and cable breakage. Safety is a priority—each unit includes:

- Rope break and overload detection

- Integrated operational and emergency limit switches

MTS telescopes are engineered for low-maintenance operation, with tool-free access to key components. Emergency operation is supported via hand crank or drill adapter, ensuring continued functionality even in case of drive failure.

With a modular design, our telescopes can be customized to meet specific customer needs. Power can be supplied via trailing cables or current- and data-carrying support rails.

At MTS, we prioritize quality and safety. Every product is built with premium components and complies with EN 17206 and DGUV V17 (BGV C1) standards.

OUR DIFFERENT TELESCOPE VErSIONS:

1) STUDIO-TELESCOPE.

- precise studio telescope

- up to 7m / 12m drop

- up to 60kg payload

- on studio-rails, for ceiling mount, or clamps

5) MANUAL MINI TELESCOPE.

- pole operated telescope (no motor unit)

- 30kg payload

- with or without cable

1) TLM 70 / 120 - Studio Telescope

The TLM 70 and TLM 120 motorized telescopes enable precise positioning of lighting, audio, and video equipment with a stroke length of up to 7m or 12m. The abbreviation TLM 70 / TLM 120 stands for Telescopic Lighting-Hanger (Motor) with 7000 mm / 12000 mm extension. These telescopes are also available in custom lengths and special versions to suit specific applications. Depending on the model, the load capacity is 60 kg (TLM 70) or 50 kg (TLM 120). All MTS telescopes can be fully customized to meet individual customer requirements. The Telescope can be equiped with a trolley for horizontal movement on studio rails. Alternativelywith c-clamps or ceiling mounting plate.

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

2) tlM 70/120 GV & GVM - OverGrid Telescope

The TLM 70/120 GV is a motorized overgrid telescope designed for the precise positioning of lighting, audio, and video equipment. It offers a stroke length of up to 7m or 12m, depending on the model.

The abbreviation GV stands for “Grid Motorized”, indicating a motorized vertical drop. For applications requiring horizontal movement, the GVM version includes a motorized horizontal drive. The load capacity is 60 kg (7m) or 50 kg (12m). The Grid Trolley is an integral part of the telescope, allowing manual or motorized horizontal movement.

All MTS telescopes, including their halogen-free hybrid spiral cables, can be fully customized to meet individual customer requirements.

- motorized Grid-Telescope

- motorized or manual horizontal movement

- Payload: up to 60kg (7m) / 50 kg (12m).

- Self-weight: approx 60kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- 3x 230/400V, 50Hz, 12 kg, 1,5kW, 300 Nm

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

3) TLM 165 S - Heavy-Duty telescope

The TLM 165 S is an extra-long, heavy-duty motorized telescope designed for the precise positioning of lighting, audio, and video equipment. With a stroke length of up to 16.5m and a load capacity of up to 120 kg, it is ideal for ultra-high studio ceilings and demanding load requirements.

Engineered for maximum stability and reliability, the TLM 165 S is the perfect solution for professional studios requiring heavy-duty lifting capabilities.

- payload: up to 120kg SWL

- up to 16,5m vertical drop

- safety features:

- working- and emergency limit switches at the top and the bottom

- overload detection

- cable breakage detection

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- components are designed to carry heavy loads of up to 120kg.

- tool-less design. all maintainance points can be directly viewed.

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

- Payload: up to 60kg (TLM70) / 50 kg (TLM120).

- Self-weight: approx 50kg

- Radial clearance: +/- 2 °

- Slack rope / rope break detection per load carrying device

- up to 12 m drop

- load attachment via DIN TV sleeve 29 mm

- attaches either to a trolley, or can be equiped with c-clamps or ceiling mount

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- Statically and dynamically self-locking drive

- Permanent lubrication

- Motor: 230 / 400V; 50 Hz; 0.4 kW

- Motor protection: protected against thermal overload and IP 54

- Working temperatures from -30 ° C to + 150 ° C

- Absolute position sensing with high-precision potentiometer on request

- tool-less design. all maintainance points can be directly viewed

- lubricant-free tubes (no dripping)

Choose from different control unit options:

- FCP PRO: fully automated studio control system

- FCP 900: simple yet efective control unit on sight

- Button control: for simple up/down movement of individual devices

- Wireless control units

Choose from different outlet options:

- Power Supply (Schuko, CEE, Powercon, etc.)

- DMX

- Audio

- Video

- etc.

As we manufacture our lifting equipment order-related in our factory, we can react to customer-specific change requests at any time and implement them as required. Here are some of the variable key data of our Studio Hoists:

- supply lines and sockets (e.g. Schuko, CEE, Powercon, XLR, etc)

- various load bars (length and type)

- variable stroke

- individual overload settings

- customer-specific carrying ropes

- carriages for all common running rail systems

- individual control concepts

- and more

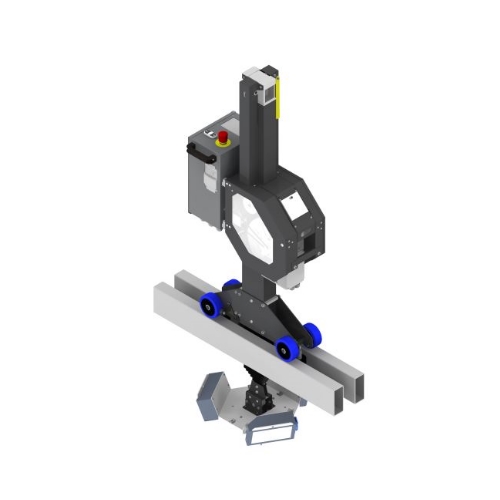

4) tlp 120 g - Manual OverGrid Telescope

The MTS Grid Ceiling Telescope is designed for mounting above a grid or catwalk, enabling the precise positioning of lighting, audio, and video equipment.

Vertical adjustment is performed manually or with an external motor (drilling machine with torque limiter DWSE 6.3). A self-locking gearing system ensures a high level of safety. Its modular design allows for easy customization to fit local conditions or specific customer requirements. When retracted, the telescope has a low overall height, optimizing space efficiency.

Built with high-precision aluminum profiles and wear-free plastic guides, it maintains a minimal radial clearance (< ±2°). The standpipe diameter is 68mm, and two cable bobbins ensure precise winding of suspension elements. A DIN TV sleeve (Ø 29mm) serves as a load receptacle. A guide roller between the support rails ensures safe and stable fixture movement.

- Payload: 60kg

- for standard grids (68mm) or custom width

- mechanical overload detection

- self-weight: 30kg

- fully compliant with the strictest safety regulations – designed according German safety standards

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

- The telescope is operated manually of with the aid of an external motor unit (drill)

5) tlp 20-60 - Manual Mini Telescope

The TLP Series is a pole-operated manual mini telescope designed for precise height adjustment of the fixtures. With a drop range between 2m and 6m, it offers flexible positioning directly from the studio floor using a standard operator pole.

For faster operation, an optional drill unit (MSB type) can be used. The TLP telescopes support a load capacity of up to 30 kg and can be equipped with an optional spiral cable for integrated power and data supply.

- Payload: 30kg

- DIN TV socket for load attachment (29mm).

- Tubes: DIN AlMgSi 0,5/F22

- Upper attachment: DIN TV spigot (28mm).

- Safety standards: EN17206, DGUV Vorschrift 17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

WHY CHOOSE MTS PRODUCTS?

MTS lighting suspension devices provide safe, reliable, and easy-to-maintain solutions for studio and stage applications.

Key Benefits:

✔ Safety is our top-priority – Oversized steel wire ropes (safety factor 10) ensure durability, early damage detection, and resistance to lateral movement.

✔ Low-Maintenance Drives – Compact, quiet, and maintenance-free drives with near-zero failure rates. The motor/gear-units are statically and dinamically self-locking.

✔ Decentralized Control – Independent motor control prevents system-wide failures and simplifies maintenance.

✔ Fire-Safe Cables – Halogen-free, reducing toxic emissions and fire hazards.

✔ Easy Maintenance – All inspection points are visible, cutting service time by up to 50%.

✔ Future-Proof Compliance – Meets EN 17206 & DIN 56950-2, ensuring long-term EU regulation compliance.

✔ Reliable Service & Warranty – 3-year warranty, 10-year spare part availability, and global service support.

MTS Expertise:

✔ 25+ years in studio & stage lifting

✔ Premium components for safety & durability

✔ Manufactured to DGUV 17 & DIN 56950-2 standards

MTS delivers end-to-end solutions – from consultation to installation, ensuring top-tier safety, performance, and reliability.

MTS TELESCOPES IN REAL-Life PROJECTS:

MTS Telescopes are installed in leading studios and venues worldwide, providing safe, reliable, and efficient lighting suspension solutions. Some of our notable projects include:

- Czeska Televice, Czech Republic

- ZDF Berlin, Germany

- Pinewood Studios, London

- BBC Studios London

- WDR Köln, Germany

… and many more,

We are proud to serve many of the world’s top broadcasters, ensuring cutting-edge lighting solutions for studios and event spaces across the globe. Have a look at our project reference list.

Siutable Control UNits:

Our motorized studio lighting suspensions are powered by a decentralized control logic, minimizing downtime and ensuring maximum operational readiness. Each suspension device is equipped with an independent motor control unit, which continuously monitors all safety-critical parameters, including:

- Overload protection

- Slack-rope detection

- Cable breakage detection

- Upper and lower working end positions

- Upper and lower emergency stop positions

Our system offers scalable automation levels, ranging from simple up/down controls to standard control panels with group selection (FCP 900) and fully automated studio control units (FCP PRO).

The FCP PRO offers the most advanced rigging control for bigger studios.

The FCP 900 controls goups with up to 10 devices.

Further questions?

contact us

CONTACT MOVIETECH

- Producs of MTS Media Technical System are globally distributed by MovieTech in Munich, Germany.

E-maIL US

- info@movietech.de